During the iAMP-Hydro project, different measures will be taken to prepare two hydropower plants (HPP) for the digitalisation needs of the future. The two plants are Asomata HPP (operated by PPC, the Greek National Energy Company) and Makrochori HPP (operated by PPC Renewables, a 100% subsidiary company of the PPC Group).

At Asomata and at Makrochori the following aspects are worked on in the project to reach the iAMP-Hydro objectives:

We present the performed work until October 2025 very brief below. For further questions, please get in contact with Ingo Ball, WIP Renewable Energies (ingo.ball@wip-munich.de).

Asomata HPP belongs to the Aliakmonas river complex, in Western Macedonia, Northern Greece. It is using a dam-toe reservoir with a useful volume of 10 million m3. The reservoir, besides supplying water for hydropower generation, is also used for supplying water to the previous pumped storage Sfikia HPP, and for irrigation purposes in the big valley of Western Macedonia. The plant operates two (2) vertical axis Francis turbine units of installed capacity 54 MW each (total 108 MW). Its average yearly production is 130 GWh, and has been in operation since 1985.

Asomata HPP and dam: view from downstream (Source: PPC)

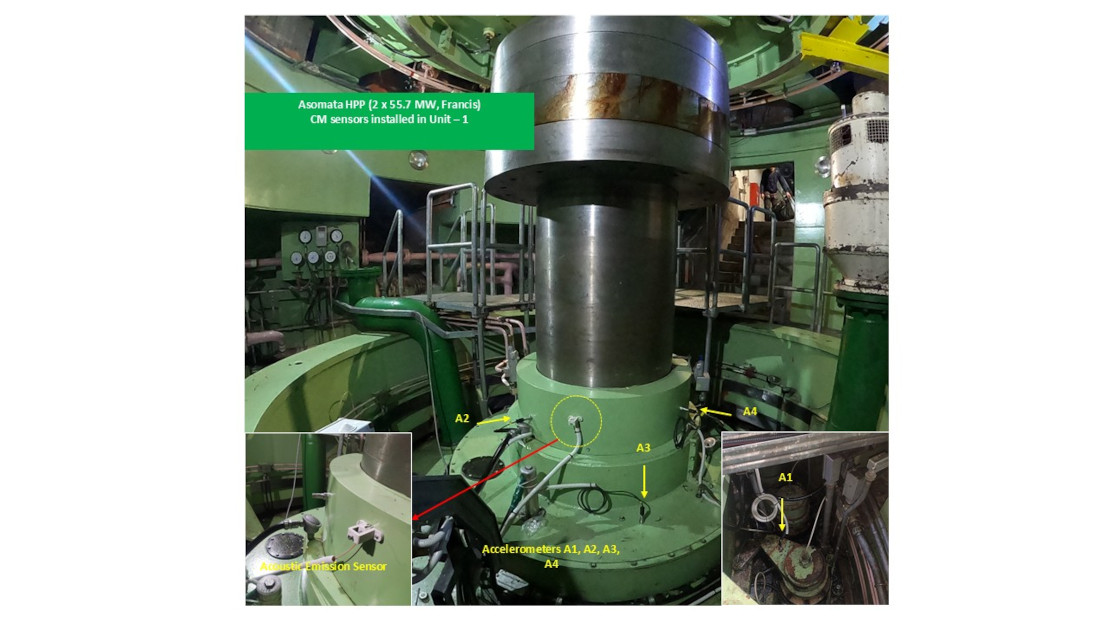

To enhance predictive maintenance and improve turbine reliability, condition monitoring systems have been deployed at the Asomata (Francis turbine) and Makrochori (Kaplan turbine) hydropower sites in Greece. The following works were done at Asomata:

Sensors and Data Acquisition

Installed sensors for condition monitoring at Asomata HPP (Source: TCD)

The sensor installation and analysis work

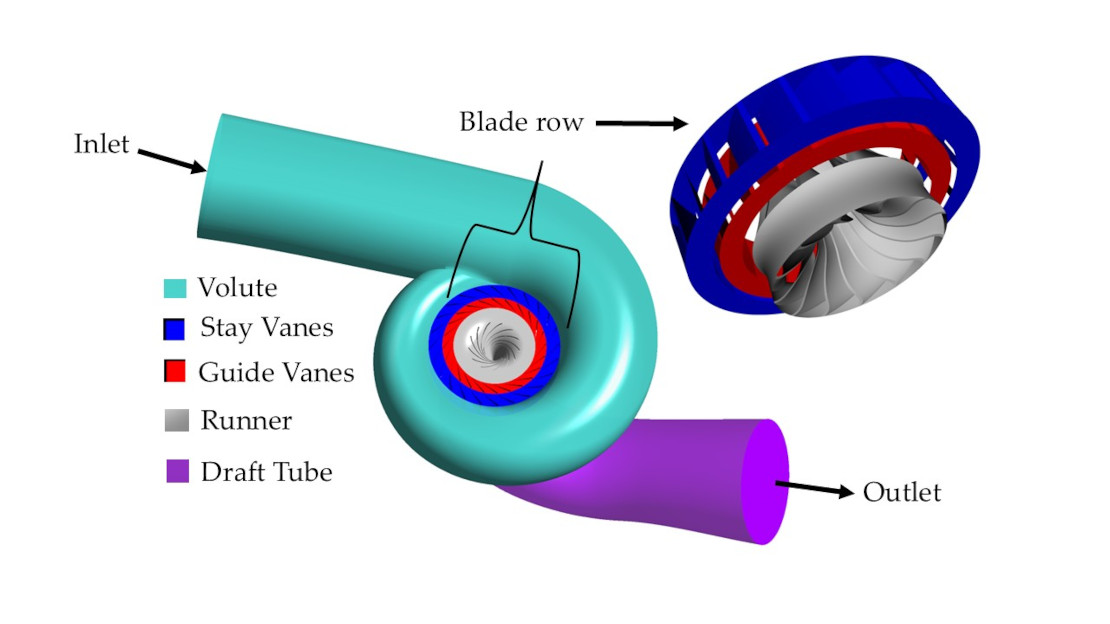

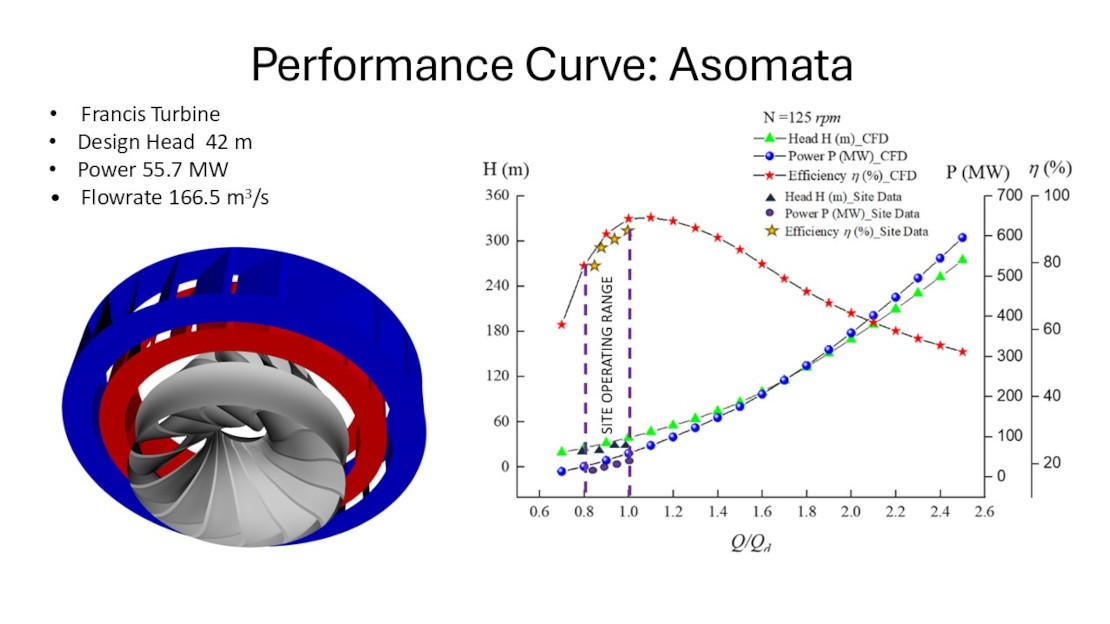

The Asomata and Makrochori pilot sites have undergone a detailed CFD analysis to simulate and predict failure mechanisms such as:

A new Inverse Design with advanced optimisation method was used to overcome the lack of detailed turbine geometry data in ageing facilities — enabling accurate, validated CFD models despite limited documentation.

CFD Models for Asomata after Reverse Engineering (Source: TCD)

These models provide essential input for the project’s predictive maintenance framework, contributing to improved reliability and performance across hydropower operations in Greece.

For more detail on Asomata refer to this Publication, ”Supporting the Digitalisation of Existing Hydropower Plants using Computational Fluid Dynamics Modelling” Renewable Energy (2025) — DOI: 10.1016/j.renene.2025.124174”

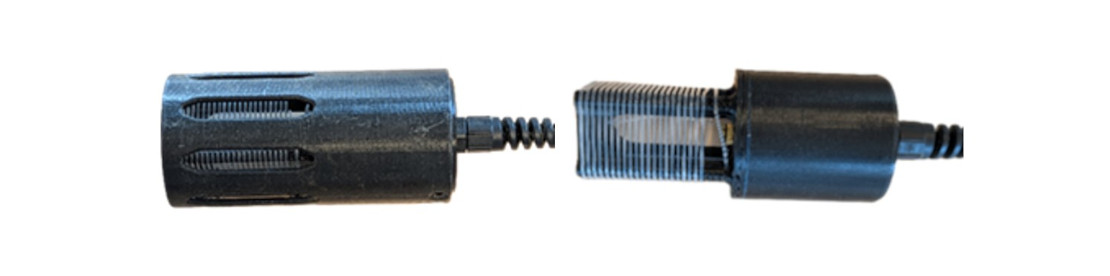

A novel environmental monitoring system with a multi-probe capable of measuring gas supersaturation, water level and temperature is operational at Asomata outlet. The system is transmitting data to online database, and environmental conditions is monitored in real time online.

Digital environmental multi-probe, with low energy consumption and no need for field calibration (Source: NORCE)

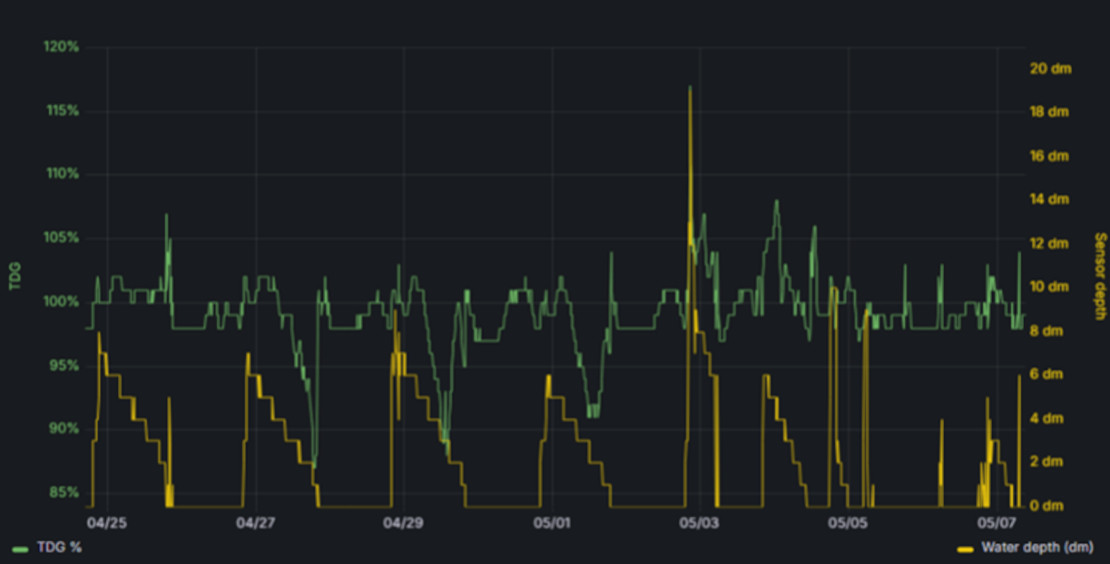

Episode with gas-supersaturation (117 %) at increased water level at Asomata outlet (Source: NORCE)

Preliminary results from Asomata, show gas supersaturation up to 117 %, usually at the same time as rapid changes in water levels (hydro peaking). An episode with rapid temperature changes at water level fluctuations at Asomata outlet was observed.

Weather-related datasets have been prepared for all iAMP-Hydro demonstration sites. For Asomata HPP, being part of a cascade of HPPs at Aliakmonas river, this makes the flow prediction a veritable challenge. Asomata HPP is one of the six case study HPPs of the iAMP-Hydro project, together with Agia Varvara reservoir / Makrochori HPP and the newly selected Ilarion HPP (for reasonable forecasting), also from Greece, and Bermejales, La Vega and Berchules from Spain.

Asomata HPP belongs to the Aliakmonas river complex, in Western Macedonia, Northern Greece, being the 4th in a 5 HPPs cascade. It is a dam-toe HPP with the reservoir having a live storage of 10 million m3. Besides supplying water for hydropower generation, the reservoir is also the lower reservoir for PSH Sfikia, and its water is used for irrigation purposes in the big valley of Western Macedonia. The plant operates 2 vertical axis Francis turbines of installed capacity 54 MW each. Its average yearly production is 130 GWh and has been in operation since 1985.

The forecasting approach for Asomata consisted of predicting the daily volume of turbined water discharged over the next seven days.

First results have shown that a prediction model based on recurrent neural networks can successfully capture the behavior of this complex HPP and produce results close to the observed averages one week in advance.

View upstream at Aliakmonas river forming Asomata HPP reservoir – rainy weather (Source PPC)

Hydrological modelling was also applied for flow forecasting. Bad results using data from Asomata HPP demonstrate that this physical modelling cannot be applied for highly regulated flows. For this reason, Ilarion HPP was introduced within case-studies, being the first reservoir in the cascade and having natural inflows. For Ilarion, hydrological models as HBV, SWAT and HEC-HMS gave satisfactory results. Instead, time series analysis tools as ARIMA, ANN, LSTM and RF, using MATLAB, were applied for one day ahead prediction for inflows, for both Asomata and Ilarion reservoirs, with very good results.

The iAMP-Hydro Platform brings together the data from the project’s results R1–R4, enabling the extraction of knowledge, under a common cloud-based platform that supports smarter, more connected hydropower operations and decision-making.

The platform supports multiple data collection modalities enabling the ingestion of information from diverse sources (sensors, monitoring systems, operational records, etc.). Once collected, data can be explored, analysed, retrieved and shared with trusted parties, through state-of-the-art tools designed to help hydropower stakeholders to extract real value from their assets.

Through its data analytics, the platform enables HPP operators to transform complex datasets into actionable insights that can improve HPPs operational and environmental performance, and enable them to make informed and evidence-based decisions. A dedicated marketplace enables secure and transparent sharing of data and derived insights. Powered by a blockchain-based framework, it guarantees data integrity, trust, full traceability of the exchange process; fostering trusted and reliable collaboration.

By combining strong data governance and data management mechanisms, advanced analytics, secure data exchanges and semantic interoperability, the iAMP-Hydro Platform establishes a strong foundation for more efficient, trusted and sustainable hydropower operations management.

The iAMP-Hydro Project invites interested stakeholders to learn and discuss the project results in the Community of Practice of the iAMP-Hydro project. We share there our latest results, and you can also watch the Co-Development Workshops which were organised before. There is, of course, no charge for registration as we are eager to discuss the future of digitalisation in hydropower together with you.

Register for free at: